How Cabex Ex EUF1- HT Cable Gland Ensures Safety in Hazardous Area Environments: Expanding Our Dealers Network Now!

Apr 25, 2025

9 min read

0

101

As industries push the boundaries of innovation in the oil and gas, petrochemical, and mining sectors, the need for uncompromising safety solutions continues to grow. Among the many components that ensure operational safety in hazardous environments, cable glands are a critical — yet often underappreciated — part of the system. Industry exhibitions such as Cabex have brought this to light by showcasing cutting-edge innovations designed to meet global safety standards and support industrial excellence.

Table of Contents

Why Cable Glands Matters in Hazardous Areas (IECEx Certified)

Comparative Overview of Cabex High-Temperature Cable Glands for Hazardous Areas

Certified for Safety: Meeting International Standards with the Ex E1FU-HT Cable Gland

Optimized for Harsh Environments: Material Engineering of the Ex E1FU-HT Cable Gland

From Precision to Protection: Cable Glands as a Critical Safety Asset

SPT Maju x Cabex: Engineering Reliable Connections

SPT Maju Sdn. Bhd. is a trusted Oil and Gas Solutions Provider and Power Systems Engineering specialist based in Miri, Sarawak. As a licensed vendor for Petronas, the company is committed to delivering reliable and innovative engineering solutions to Malaysia’s energy sector.

In line with this commitment, SPT Maju Sdn. Bhd. is pursuing a strategic partnership with Cabex — a globally recognized manufacturer of Industrial and Hazardous Area Cable Glands, Earthing Accessories, and Lightning Protection Accessories. Established in 1995 in Jamnagar, Gujarat, Cabex has evolved from producing precision-turned brass components to becoming a trusted global supplier of high-quality electrical products.

SPT Maju Sdn. Bhd. is seeking to procure Cabex’s cable glands, designed for high temperatures in hazardous areas. Cabex was selected due to its IECEx and ATEX certifications, consistent and trusted performance, competitive pricing, and ready stock availability — all of which support SPT Maju Sdn. Bhd.'s objective to equip Malaysia’s oil and gas industry with world-class products and expertise.

Understanding Hazardous Area Cable Glands

Cable glands are mechanical devices designed for cable entry, typically used in electrical, instrumentation, control, and automation systems, as well as for lighting, power, and telecommunications applications. In certain environments, standard cable glands may not provide sufficient protection—this is where hazardous area cable glands come into play. These specialized devices are designed for cable entry into electrical equipment located in areas with explosive gases or dust. Their main function is to secure cables to equipment like junction boxes and motors, while ensuring an explosion-proof seal that prevents any spark or flame from escaping the enclosure.

Why Cable Glands Matters in Hazardous Areas (IECEx Certified)

Cable glands do much more than simply secure cables in place. They act as the first line of defence in maintaining the integrity of electrical systems within high-risk environments. In hazardous areas where flammable gases, vapours, or dust may be present, a single failure in an electrical connection could result in catastrophic consequences. Certified hazardous area cable glands play a vital role in mitigating these risks.

Beyond mechanical retention, these glands provide crucial environmental sealing and flameproof barriers that prevent the transmission of sparks or flames from the inside of enclosures to the external atmosphere. They also help maintain ingress protection (IP ratings) by sealing entry points against dust, water, and other contaminants—critical for both safety and long-term equipment reliability.

Additionally, the use of appropriately rated cable glands ensures compliance with international standards such as IECEx, ATEX, or UL, which are often legally mandated in industries like oil and gas, chemical processing, and mining. This compliance not only reduces liability but also supports safe inspection, maintenance, and repair procedures. In short, cable glands are not just accessories—they are essential safety components that protect lives, equipment, and infrastructure in potentially explosive atmospheres.

Key Functions of Hazardous Area Cable Glands

o Environmental Protection: Hazardous area cable is engineered to seal around the cable sheath, effectively preventing the ingress of dust, moisture, and other environmental contaminants. This protection is crucial in maintaining the integrity and performance of sensitive electrical components within the enclosure, especially in challenging industrial settings like offshore platforms or chemical plants where exposure to harsh elements is constant.

o Cable Pull-out Resistance: A secure connection between the cable and the equipment is vital in preventing accidental disconnections or internal damage. Cable glands are designed to provide robust mechanical retention, ensuring the cable remains firmly attached even when subjected to vibration, tension, or pulling forces – common

o Earth Continuity: For armoured cables, maintaining electrical grounding is critical. Cable glands facilitate a low-resistance path for fault currents by bonding the cable armour to the equipment earth. This function not only protects personnel from electric shocks but also helps prevent potential ignition sources by safely directing stray electrical currents away from hazardous atmospheres.

o Explosion Prevention: In environments where explosive gases or dust present, even a small spark can lead to catastrophic consequences. Hazardous area cable glands are constructed to prevent these substances from entering the enclosure and interacting with electrical components. By maintaining a tight seal and isolating internal sparks, these glands serve as a first line of defence against explosions.

o Flameproof and Explosion Proof: Certain types of cable glands, such as Ex d certified glands, are specifically built to contain an internal explosion and prevent the flame or hot gases from escaping into the surrounding atmosphere. This design ensures that even if an ignition occurs inside the enclosure, the explosion will be safely contained and will not propagate outside, where it could ignite more flammable material.

o Increased Safety: Other glands, such as Ex e or Ex i types, are focused on minimizing the chances of an ignition occurring in the first place. They use enhanced sealing, specialized components, and non-sparking materials to ensure there is no opportunity for arcs, sparks, or excessive heat—making them ideal for applications where continuous operational safety is a priority.

In summary, cable glands in hazardous areas are essential for safety, protecting equipment and personnel from the dangers of flammable atmospheres by creating a secure seal and preventing the entry of hazardous materials.

Comparative Overview of Cabex High-Temperature Cable Glands for Hazardous Areas

Cabex Hazardous Area High Temperature Cable Glands come in three models—Ex A2F-HT, Ex CFU-HT, and Ex E1FU-HT—each tailored for specific application needs. When selecting between the Ex A2F-HT, Ex E1FU-HT, and Ex CFU-HT cable glands, the most suitable choice ultimately depends on the type of cable being used and the level of mechanical and environmental protection required. The Ex A2F-HT is specifically designed for unarmoured and braided cables. It features a straightforward sealing mechanism using an inner displacement seal, which provides reliable protection for non-armoured applications. Its electrical classification is Category A, and it offers moderate retention strength classified as Class B. This makes it a practical and efficient choice for simpler cable installations where armoured protection is unnecessary.

In contrast, both the Ex E1FU-HT and the Ex CFU-HT are engineered to accommodate a variety of armoured cable types, such as wire braid, steel tape, and single wire armour. These models offer enhanced mechanical retention, both rated as Class D, which is higher than that of the A2F-HT. The Ex E1FU-HT distinguishes itself further by incorporating a dual-sealing system—combining an inner displacement seal and a load retention outer seal. This design allows it to seal both the cable’s inner bedding and its outer sheath, providing a comprehensive barrier against ingress and strain. Its electrical classification, however, is Category B, slightly lower than that of the A2F-HT, but this is balanced by its superior mechanical design and versatility. As a result, the Ex E1FU-HT is especially suitable for critical environments where both mechanical strength and sealing integrity are paramount.

The Ex CFU-HT, while also intended for armoured cables, employs only a load retention outer seal. It does not provide sealing at the inner bedding, which makes it somewhat less comprehensive than the E1FU-HT in terms of sealing performance. Nevertheless, it still offers solid protection and is suitable for less demanding installations where the extra layer of sealing may not be necessary.

In conclusion, while all three cable glands are manufactured to high standards and share many similar specifications, such as ingress protection rating (IP66/IP68), temperature tolerance, and enclosure protection (IK10), the Ex E1FU-HT stands out as the most robust option for armoured cable applications which SPT Maju is currently procuring. It combines superior mechanical retention with dual sealing capability, making it the most versatile and secure choice among the three. The Ex A2F-HT remains a reliable and efficient option for non-armoured cables, and the Ex CFU-HT offers a good balance for standard armoured installations that do not require dual sealing.

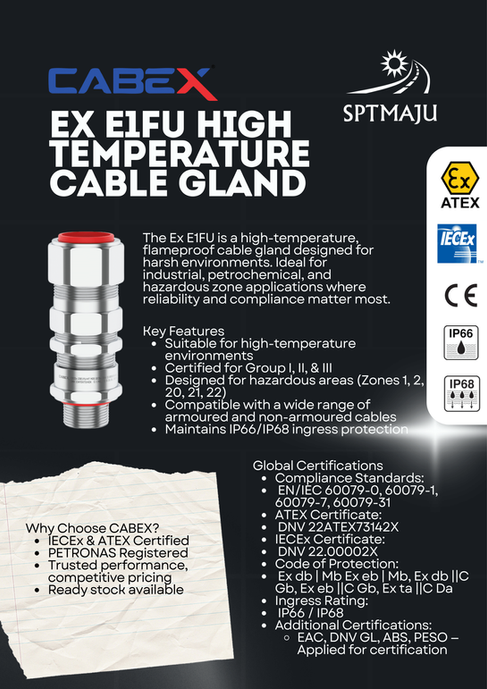

At present, our pilot partnership with Cabex brings us to the forefront of hazardous area cable solutions. We are actively exploring dealership opportunities with reliable suppliers to expand the reach of Cabex’s high-performance products. SPT Maju Sdn. Bhd. is well-equipped to supply a full range of Cabex offerings, including standard and hazardous area cable glands, conduit fittings and accessories, cable ties, earthing accessories, lightning protection systems, conductors, fasteners, and fixings. However, the current focus is on the top-of-the-line Ex E1FU-HT hazardous area high-temperature cable gland. Specifically designed for armoured cables, this model features a robust dual-sealing system and high mechanical retention (Class D), making it the most secure and versatile option among the Cabex range—ideal for critical environments requiring superior safety and durability.

Certified for Safety: Meeting International Standards with the Ex E1FU-HT Cable Gland

When operating in hazardous areas, compliance with international standards is not optional — it is a vital safeguard against operational risks. The cable glands showcased at Cabex are designed to meet rigorous global safety and performance certifications, ensuring dependable service in the harshest industrial environments. Since SPT Maju Sdn. Bhd. is procuring the Ex E1FU-HT, it’s essential to understand the international standards and certifications this product complies with — a crucial factor in ensuring safety, reliability, and regulatory compliance in hazardous locations.

Global Certification Overview

· Compliance Standards: Cabex cable glands are designed and tested in accordance with EN/IEC standards 60079-0, 60079-1, 60079-7, and 60079-31, covering equipment used in explosive gas and dust atmospheres.

· ATEX Certification: Certified under DNV 22ATEX73142X, these cable glands are approved for use in explosive atmospheres throughout the European market.

· Code of Protection

o | M2 || 2G 1D — Signifying suitability for mining and industrial explosive environments.

o IP66 / IP68 — Providing robust dust and water ingress protection.

· IECEx CertificationIECEx DNV 22.0002X certifies that the glands conform to global safety standards for explosive atmospheres.

· Protection Codes under IECEx

o Ex db | Mb — Flameproof protection for mining.

o Ex eb | Mb — Increased safety for mining.

o Ex db || C Gb — Flameproof protection for Group II gases, Zone 1.

o Ex eb || C Gb — Increased safety for Group II gases, Zone 1.

o Ex ta ||| C Da — Dust protection for Zones 20, 21, and 22.

· Additional Certifications

o EAC Certificate (Eurasian Customs Union) — Application in progress.

o DNV GL Certificate (marine and offshore assurance) — Application in progress.

o ABS Certificate (American Bureau of Shipping) — Application in progress.

o PESO Certificate — Approved (A/P/HQ/GJ/104/6052 (P568100)) by the Petroleum and Explosives Safety Organisation of India.

Optimized for Harsh Environments: Material Engineering of the Ex E1FU-HT Cable Gland

Selecting the appropriate material for cable glands is crucial not only for durability but also for ensuring mechanical strength, corrosion resistance, and sustained performance in extreme conditions. The cable glands featured at Cabex reflect this commitment through a variety of material options designed to suit different industrial applications. In the case of SPT Maju Sdn. Bhd. and their procurement of the Ex E1FU-HT cable gland, understanding the material composition is essential to ensure long-term reliability and compatibility with the demanding environments in which it will operate.

Standard Gland Material:

Brass (BS EN 12164 / Grade CuZn39Pb3) — A widely used choice for its excellent combination of strength, corrosion resistance, and machinability.

Seal Material:

Thermoset Elastomer — Known for its high thermal stability and chemical resistance, ensuring consistent sealing even under fluctuating temperatures and harsh environmental conditions.

Credit Image Via Sync Lync

Optional Gland Materials:

Brass Nickel-Plated

Brass Electroless Nickel-Plated

Stainless Steel (SS316 & SS316L)

These optional materials are selected to meet the specific demands of different environments — from marine and offshore installations to chemical plants and corrosive industrial settings where superior resistance and longevity are essential.

Cable Compatibility:

Selecting the correct cable gland also requires consideration of the cable's armour type. Each gland is engineered to securely terminate and seal various armoured cable designs commonly used in hazardous environments:

Wire Braid Armour (WBA)

Strip Armour (SA)

Pliable Wire Armour (PWA)

Steel Tape Armour (STA)

Single Wire Armour (SWA)

Aluminium Wire Armour (AWA)

This versatility ensures that the gland not only provides mechanical retention and electrical continuity but also accommodates the diverse armoured cable constructions used across oil & gas, mining, and heavy industrial sectors.

From Precision to Protection: Cable Glands as a Critical Safety Asset

As industries operating in hazardous environments continue to prioritize safety, the role of certified, high-performance components like cable glands becomes increasingly indispensable. The strategic alignment between SPT Maju Sdn. Bhd. and Cabex underscores a shared commitment to engineering excellence, regulatory compliance, and the safeguarding of both people and infrastructure. With solutions like the Ex E1FU-HT cable gland—engineered for superior sealing, mechanical retention, and certified global safety standards—SPT Maju is poised to enhance the reliability and resilience of Malaysia’s oil and gas sector. Cable glands may be small in size, but their impact on operational safety is undeniably significant. By investing in trusted, field-proven technologies, industries can move forward with confidence, knowing that their most critical systems are protected at the point of connection.

*Disclaimer: SPT Maju Sdn Bhd is a licensed and registered vendor for Petronas and we are representing Cabex as our principle partner*